Background

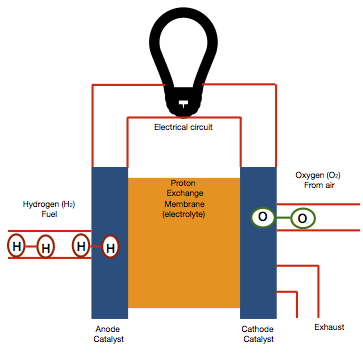

Simple animation of how a PEM Fuel cell works.

Hydrogen is fed into the Anode, where the electrons produce the current,

while the hydrogen protons are passed through the proton exchange membrane.

Oxygen is passed across the cathode, where the hydrogen protons combine with

the oxygen to produce water, which is removed along with excess oxygen and heat.

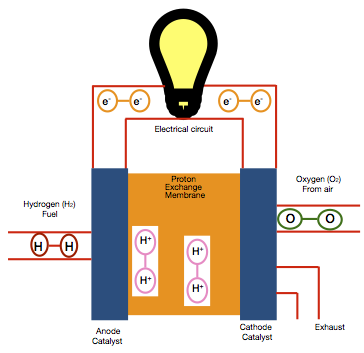

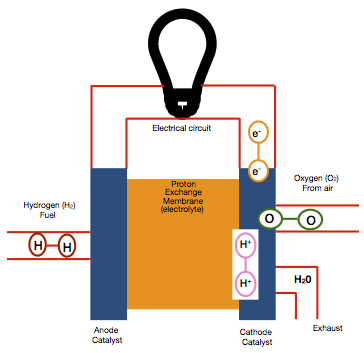

Simple animation of how a PEM Fuel cell works.

Hydrogen is fed into the Anode, where the electrons produce the current,

while the hydrogen protons are passed through the proton exchange membrane.

Oxygen is passed across the cathode, where the hydrogen protons combine with

the oxygen to produce water, which is removed along with excess oxygen and heat.

The UKs Climate Change Act (2008) has a target to reduce emissions by 80% by 2050, with a closer target of 34% by 2020. Therefore, many initiatives and research has emerged to aid in reaching these targets. The UK energy sector has to migrate towards supplying innovative, high quality, high reliable, low or zero emission energy generation sources. Coupled with this are the performance demands required for these innovative solutions to match or better that of current power generation sources. Hydrogen and fuel cells have emerged as potential initiatives that could serve as alternative energy sources, with characteristics of being zero emission energy conversion and power generation devices. They are currently being engineered for a range of applications including stationary power, automotive, aerospace and consumer electronics. Each application presents its own set of requirement for the fuel cell system including performance, operating range and cost. With the introduction of a new technology into markets where existing products are highly reliable requires that this aspect of the system performance must match customer expectations which are demanding for a new product.

The future of hydrogen and fuel cell technology depends on being able to: (i) reduce current high capital cost, (ii) allow fuel flexibility, (iii) permit system integration with high efficiencies, (iv) have superior reliability and durability to provide power for long continuous periods of time, (v) address the fuel and human resource infrastructure challenge, and (vi) understand and adhere to the governmental rules and regulations regarding siting, insuring, and certifying fuel cell products.

However, the area of reliability and durability assessment of fuel cells is still in its infancy. Understanding the behaviour of the fuel cells and the effects of its failure modes is critical if an optimal design is to be created. Although several work have been performed to understand the failure mode effects within polymer electrolyte membrane (PEM) fuel cells, many of these studies relate to single subsystems and do not consider subsystem integration within the whole system, a necessity in producing an optimal and robust system, which is to be addressed in this project. Coupled with the inherent reliability of the system is the requirement to maximal performance over its lifetime, producing commercial viability. An effective asset management strategy is required to fill a current research gap, which requires integration of maintenance and in-situ diagnostics. However despite considerable research on fault diagnostics and the wide variety of methodologies available, it remains a relative immature science with many problems still to be overcome to enable its confident, widespread application to complex systems in many industries. With incorporation of effective fault diagnostic methodologies into an asset management infrastructure would bridge the gap to informed lifetime prediction, which is also addressed in the project. Given the increasing amount of data that is to be produced with increased use of these power sources, managing and understanding the data to make informed decisions is to be critical in maximising the remaining lifecycle of the fuel cell. This diagnostic capability embedded within an information infrastructure is an area addressed in this project.

Overview

RESILIENCE aims to improve the current real-world environment durability levels, hence improving the performance criteria, through:

- Understanding of the state of the cell/stack;

- Dealing with data currently obtained in an informed manner;

- Support and decision making ability through the lifecycle to optimise performance;

From RESILIENCE, an optimal integrated fuel cell system design will be developed, which encompasses an intelligent health monitoring capability for maximised lifecycle performance. This will be achieved within a real-time dynamic and adaptive intelligent lifecycle infrastructure yielding the increased optimised performance of cells (e.g. self: -monitoring, -adapting, -optimising and -protecting). Providing an intelligent information infrastructure leading to smarter, optimised cells will require leading edge research to semantically model relationships between the cell and environment data coupled with the necessity of performance techniques which enables systems to be optimally designed for reliability, with an intelligent diagnostic and prognostic capability.